Sealed Integrity: The Craft of Hermetic Feedthroughs

In the world of electronics and technology, ensuring the integrity of sealed components is vital for the proper functioning and longevity of devices. One critical component that plays a significant role in achieving this sealed integrity is the hermetic feedthrough. Let’s delve into the craft of hermetic feedthroughs and understand their importance in various industries.

What Are Hermetic Feedthroughs?

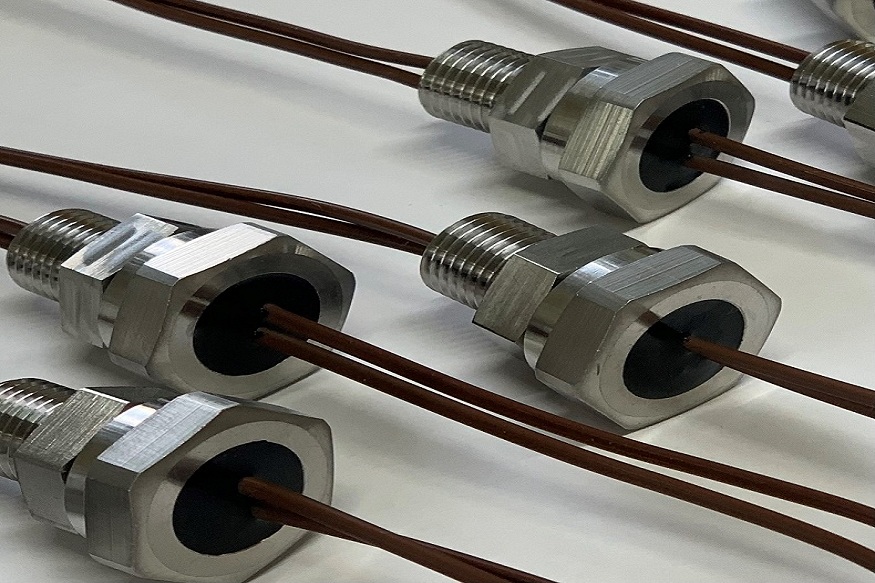

Hermetic feedthroughs are specialized components that provide a sealed passageway for electrical, optical, or mechanical signals to pass through a barrier. These barriers can include walls, enclosures, or vacuum chambers. The primary purpose of hermetic feedthroughs is to maintain a gas-tight or vacuum-tight seal while allowing signals to transfer across the sealed barrier without compromising the integrity of the system. In essence, hermetic feedthrough act as a conduit for transmitting signals while preventing any harmful elements from entering or escaping the sealed environment. This makes them essential components in applications where reliability, longevity, and performance are critical factors.

The Craftsmanship Behind Hermetic Feedthroughs

The craft of manufacturing hermetic feedthroughs requires precision engineering, meticulous attention to detail, and adherence to strict quality standards. These components are typically made from materials such as glass, ceramic, or metal, depending on the specific requirements of the application.

The manufacturing process involves carefully sealing the electrical conductors or optical fibers within the feedthrough body to ensure a leak-proof and durable seal. Specialized welding, soldering, or brazing techniques are used to create a hermetic bond between the feedthrough and the sealing material, such as the enclosure or wall.

Applications of Hermetic Feedthroughs

Hermetic feedthroughs find extensive use in a wide range of industries and applications where sealed integrity is paramount. Some common applications include:

- Medical Devices: Hermetic feedthroughs are used in implantable medical devices such as pacemakers, defibrillators, and neurostimulators to provide a reliable and safe connection for electrical signals.

- Aerospace and Defense: In aerospace and defense applications, hermetic feedthroughs are utilized in communication systems, radar systems, missile guidance systems, and other critical electronic equipment.

- Semiconductor Manufacturing: Hermetic feedthroughs play a crucial role in semiconductor manufacturing processes, where a controlled environment is essential to prevent contamination and ensure the quality of the final product.

Benefits of Hermetic Feedthroughs

The use of hermetic feedthroughs offers several key benefits, including:

- Reliability: Hermetic feedthroughs provide a robust and dependable solution for transmitting signals across sealed barriers without risk of leakage or contamination.

- Longevity: Due to their durable construction and superior sealing properties, hermetic feedthroughs have a long service life, making them ideal for applications requiring extended reliability.

- Performance: By maintaining a sealed environment, hermetic feedthroughs help preserve the performance and efficiency of electronic and mechanical systems, ensuring optimal functionality.

In conclusion, the craft of hermetic feedthroughs plays a crucial role in enabling sealed integrity in various industries and applications. These specialized components are designed to provide a reliable and durable solution for transmitting signals across sealed barriers while maintaining the integrity of the system. With their precision engineering and meticulous craftsmanship, hermetic feedthroughs offer a dependable and long-lasting solution for achieving sealed integrity in critical electronic and mechanical systems.